Ammobia claims breakthrough in ammonia production by reworking Haber-Bosch process

Ammobia, a U.S.-based startup, claims to have reinvented a core element of ammonia production by modifying the century-old Haber-Bosch process, potentially reducing costs by up to 40% and lowering greenhouse gas emissions from one of the world’s most carbon-intensive industrial processes.

The company has raised $7.5 million in seed funding to scale up the technology. Investors include Air Liquide’s venture arm ALIAD, Chevron Technology Ventures, Chiyoda Corporation, MOL Switch, and Shell Ventures.

Ammonia is a cornerstone of modern agriculture, underpinning global fertilizer supply and food production. It is also increasingly viewed as a potential low-carbon energy carrier, with countries such as Japan and South Korea incorporating ammonia into industrial and transportation decarbonization strategies. Advocates argue ammonia has advantages over hydrogen, including higher energy density and a more established global transport and storage infrastructure.

“The big advantage of ammonia is that it’s much easier and more cost-effective to transport and store,” said Ammobia co-founder and Chief Executive Karen Baert. “That opens up a range of opportunities.”

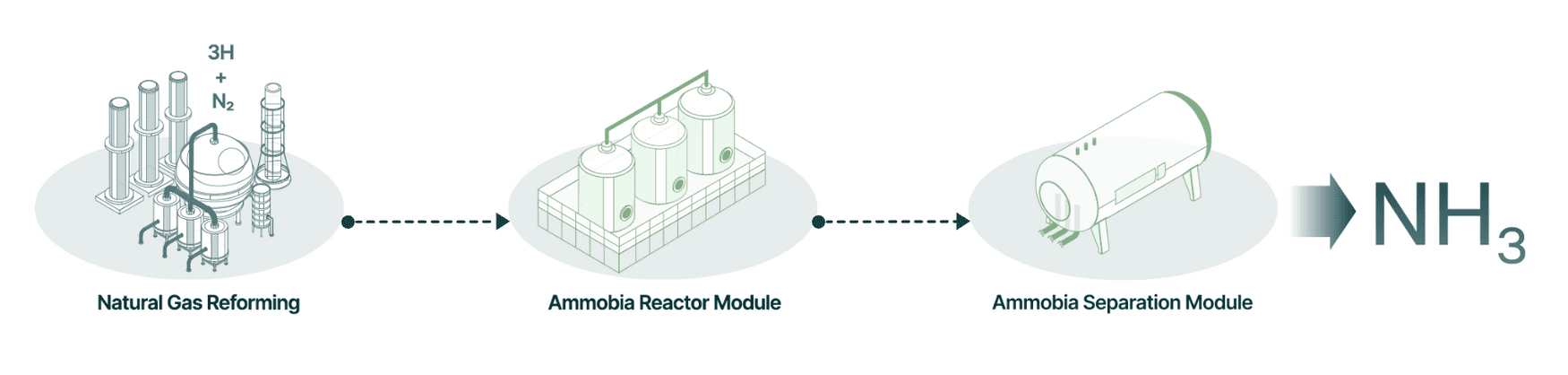

Those opportunities, however, depend on cleaning up ammonia production. Conventional Haber-Bosch facilities account for nearly 2% of global greenhouse gas emissions, largely because the process requires high temperatures of about 500 degrees Celsius and pressures near 200 bar, typically powered by fossil fuels. Most of the hydrogen feedstock is also derived from natural gas through steam methane reforming.

Ammobia says its redesigned process operates at temperatures about 150 degrees Celsius lower and at roughly one-tenth the pressure of traditional plants. The company argues this would reduce energy use and emissions even if fossil fuels remain part of the energy mix.

Lower operating conditions also translate into capital savings. Because the process does not require extreme heat and pressure, Ammobia can use smaller, less expensive pumps and equipment, potentially reducing upfront costs for producers.

The approach could give ammonia manufacturers new flexibility. Historically, producers have had limited options to cut costs beyond sourcing cheaper heat or hydrogen, often defaulting to natural gas in regions such as the United States. Ammobia says its technology is compatible with any hydrogen or heat source, including renewable energy.

Operating at lower pressure makes it easier to ramp production up and down, a feature that could enable ammonia plants to utilize surplus renewable electricity to generate hydrogen and convert it into ammonia without incurring costly storage.

“Our technology is very compatible with renewable energy,” Baert said. “You don’t need to store hydrogen or store electricity, and in those situations we have the strongest cost advantage.”

The company is also targeting smaller, modular production units. While conventional ammonia plants typically produce between 1,000 and 3,000 metric tons per day, Ammobia’s planned commercial units are designed to produce about 250 tons per day. Additional capacity can be added by installing multiple units, Baert said.

Ammobia has not disclosed detailed technical specifications, but it has filed a patent for a reactor system that utilizes a sorbent to remove ammonia as it forms, thereby freeing space on the catalyst surface and enabling the reaction to proceed at lower energy levels. Academic research has also pointed to alternative catalysts, such as manganese nitride, as potential enablers of lower-energy ammonia synthesis.

The startup has operated a small demonstration unit for about a year. The new funding will be used to build a pilot plant that produces roughly 10 tons per day, incorporating all the features of the intended commercial design.

“With that modular approach, we can build projects faster and start at a medium scale,” Baert said. “We see strong interest from customers, and there is no comparable solution on the market today.”

Enjoyed this story?

Every Monday, our subscribers get their hands on a digest of the most trending agriculture news. You can join them too!

Discussion0 comments