Martin Engineering launches fourth-generation railcar opener

Martin Engineering has introduced the fourth generation of its railcar opener, a redesigned unit intended to improve worker safety and ease of use while reducing unloading delays and costs.

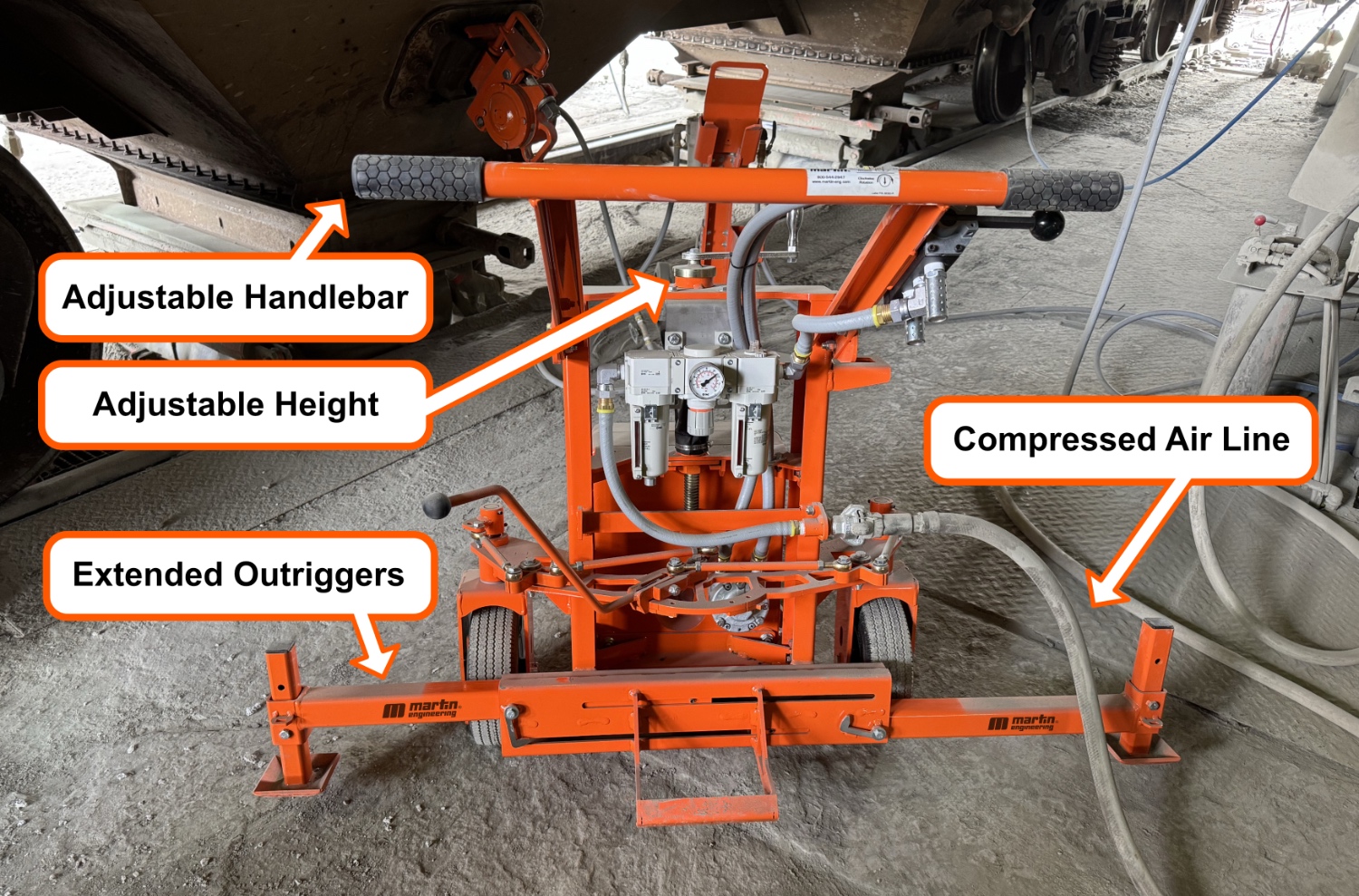

The Martin Gen 4 Railcar Opener is a two-wheeled, non-impacting device that delivers 3,750 ft/lbs (5,080 N-m) of torque to open or close railcar gates, including poorly maintained ones. It features lateral turning wheels, outrigger support for stability, and a height-adjustable drive shaft to match different capstan positions. A new “stepped” drive tip increases surface contact with the railcar’s capstan, minimizing wear and rollback under load.

Marty Yepsen, business development manager for railcar unloading products at Martin Engineering, said the model was developed using customer feedback. “We approached this with reliability and safety in mind, using heavy-duty materials for long equipment life. The result is a non-impacting opener that can compete with impacting-type openers. In fact, given the controlled force of the Gen 4, it may be preferred,” he said.

The opener weighs 305 lbs (139 kg) and is designed for a single worker. Adjustable handlebars and “Never Flat” tires improve maneuverability, while pivoting wheels allow the unit to move with a traveling capstan. The system also operates at 88 dBa, reducing workers’ noise exposure.

According to Martin, the design helps minimize demurrage costs by reducing stalling during unloading and contributes to lower long-term operating costs through safer, more efficient handling.

Enjoyed this story?

Every Monday, our subscribers get their hands on a digest of the most trending agriculture news. You can join them too!

Discussion0 comments